Hallmarks of Effective Food Safety

April 1, 2020 | 8 min to read

The article emphasizes the alarming global prevalence of foodborne illnesses, with an estimated 600 million people affected annually, leading to 420,000 deaths and substantial health losses. In the U.S., the CDC reports that 48 million individuals get sick each year. Listeria poses a significant risk in supermarket delis, necessitating stringent control measures including sanitary equipment design and effective employee training. Proper time/temperature controls and safe handling practices are essential to mitigate these risks and protect consumer health.

The numbers are staggering. According to the World Health Organization, an estimated 600 million— almost one in 10 people in the world—fall ill after eating contaminated food and 420,000 die every year, resulting in the loss of 33 million healthy life years (DALYs). Children under five years of age carry 40 percent of the foodborne disease burden, with 125,000 deaths internationally every year.

In the U.S. alone, one in six Americans or 48 million people get sick, 128,000 are hospitalized and 3,000 die of foodborne dis- eases, according to the Center for Disease Control (CDC).

Knowing the risks and how to mitigate them should always be top of mind at the retail level in delis. Also, being aware of new developments and having the appropriate protocols in place are key in keeping a safe environment and protecting customers.

Knowing the Risks

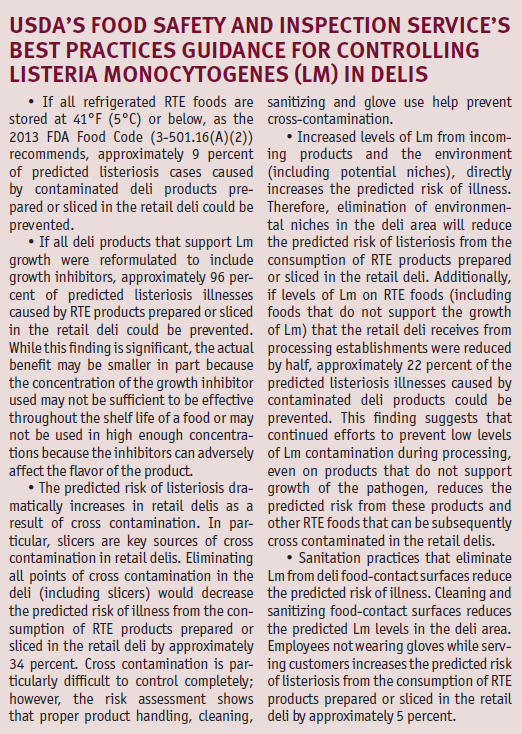

Listeria is the biggest risk in supermar- ket delis, so it is imperative that a program to control this pathogen be in place.

“This includes utilizing equipment with a sanitary design; appropriate product han- dling, including time/temperature controls; cleaning and sanitizing; environmental monitoring plans; incoming ingredient man- agement; and team member training,” says Rade Jankovic, senior account manager of retail services at NSF International in Ann Arbor, MI.

Because human-borne bacterial patho- gens and viruses, like norovirus, hepatitis A and shigella, are transmissible through food, there are some controls that help reduce risk.

“These include exclusions and restric- tions policies related to sick employees as defined in the FDA Food Code; personal hygiene policies and procedures, including hand washing; no bare hand contact with ready-to-eat foods; and training for all team members,” says Jankovic.

Also, there are controls in place that help reduce the risk of toxin-producing bacterial pathogens that may thrive in ready-to-eat foods exposed to excessive time/temperature abuse.

“Delis should be sure to have adequate time/temperature controls during receiving, storage, preparation and display,” says Jankovic. “Also, cooling procedures that meet the FDA Food Code standards should be utilized.”

“These include safe product handling; separating raw meats from ready-to-eat foods during receiving, storage, preparation and display; cleaning and sanitizing; and adequate facilities that promote safe prod- uct handling,” says Jankovic. “In addition, there should be adequate cooking tempera- tures of raw animal products, as well.”

There are hot spots in the deli that should be the focus of every deli’s food

safety program.

“There is a possibility of getting Listeria into the deli case, whether through slic- ing machines or deli boards, and develop a harborage,” says Marty Mitchell, tech- nical director at the Refrigerated Foods Association (RFA) and director emeritus of Certified Laboratories, Melville, NY. “If you’re not reducing it to zero, you’re recon- taminating product every day.”

New Developments

There are constantly updated regulations, requirements and information on food safety that are important to keep abreast of.

“Retailers should be aware of the FDA’s recently announced New Era of Smarter Food Safety initiative, which strives to develop a new approach to food safety, emphasizing the use of technology and other tools to strengthen the country’s food safety system,” says Jankovic at NSF International. “Also, FMI recently updated its Listeria Action Plan for Retailers to assist stores with the develop- ment of Listeria control programs in their operations.”

Much of the focus this year will be on the Food Safety Modernization Act (FSMA), which was signed into law in January of 2011. This grants the FDA more authority over product recalls as well as additional regulations. It was prompted after an outbreak of foodborne illnesses in the early 2000s.

“FSMA is one of those topics we should focus on for 2020,” says Eric Richard, education coordinator for the Madison, WI-based International Dairy Deli Bakery Association (IDDBA). The association has planned a FSMA Summit in Washington, D.C. for its members. “FSMA is a large, encompassing policy, and there are lots of questions with it. It is one of those food safety areas that continues to be important for our industry and will continue to be.”

He says superrmarket delis need to do what they can to stay in compliance, not just from a food safety perspective, but also for transparency.

“Manufacturers and retailers require tracked sources of contamination,” says Richard. “The consumer can get the story behind a food’s origin, whether from a farm or manufacturing facility where the product was created.”

He predicts this will become more com- monplace with blockchain technology, which provides consumers with access to labels through their smartphones and supermarkets and the means to access large amounts of data traveling through the supply chain. This in-depth tracking helps ensure food quality.

“We will see more interest in blockchain technology, as it’s a trend that’s continu- ing to grow,” says Richard. “Another thing we’re seeing in the food safety realm is labeling continues to be important. People who have food allergies and cannot ingest ingredients are checking labels.”

Expiration dates also fall into the food safety arena, and ensuring product is not expired is key.

Proper food handling at the store level cannot be overstated.

The Right Steps

There are a number of steps that are hallmarks of an effective food safety pro- gram for supermarket delis.

“This includes a strong food safety cul- ture; food safety policies and procedures based on risk assessment and sound science; an effective, on-going training program for all team members; active managerial con- trols; and well-maintained facilities and equipment that promote safe product han- dling, such as NSF International-certified food equipment,” says Jankovic at NSF.

He emphasized that it’s important for company leaders to establish a food safety culture to ensure all team members in the supermarket deli buy in and stay engaged with the program every day.

“Design your program based on risk assessment to help you identify critical food safety areas in your operation and priori- tize efforts and resources,” says Jankovic. “Whenever possible, utilize the latest tech- nology available to the industry to augment your food safety efforts (e.g. wireless tem- perature monitoring systems, technologies that improve traceability and outbreak responses, wearables…).”

New technologies significantly increase the speed at which food system failures can be identified, issues addressed, and pertinent warnings and alerts disseminated where needed.

“Re-enforce food safety knowledge through on-going training and daily monitoring of employee practices,” says Jankovic. “Food handling in a retail deli poses numerous challenges that, if not managed properly, could lead to serious consequences with public health implications.”

It’s the food manufacturers’ job to make sure what they’re providing is pathogen free, but it’s up to deli operators to ensure they’re not contaminating these products. “Slicing machines haven’t gotten better in terms of maintenance,” says Mitchell at RFA. “Dismantling equipment, cleaning and sanitizing mid shift, while keeping food at proper temperatures [is key].”

In terms of display cases, these need to be refilled in a way to keep old product from contaminating new product as well as being washed down and sanitized.

Fifteen years ago, RFA established its Shelf Life Protocol, which it presented at its convention last February and is avail- able on its website. Originally established in 2002 and updated and revised in 2009, this is a standardized protocol for determining the shelf life of refrigerated foods and enables individual manufacturers to com- pare their stated shelf life with the shelf life of similar products produced by other manufacturers.

“Aside from explaining the science behind food shelf life, it covers the stan- dards and how to assure safety,” says Mitchell. “Using this protocol standardizes practices and compares apples to apples.”

Product recall also is a concern, although he says this is on the downswing. “Everyone is embracing FSMA, asking what they can do to make sure food is safe,” says Mitchell. “Listeria is the focus of a USDA study and what a lot of our mem- bers concentrate on, but salmonella and e. Coli also are a concern.”

The key is to seek and destroy Listeria so if it does get into the deli area, it is erad- icated during cleaning and sanitizing. This should include periodic swab testing to ensure cleanliness and using instruments to measure residual proteins or ADP.

“There are ways to verify that the cleaning program is working properly,” says Mitchell. “It involves development of a cleaning program that is scientifically valid.”

At IDDBA, food safety is a focal point. Although it doesn’t have a certification program, the association will reimburse its retail members $2,000 annually to cover food safety certification program costs.

“We’ve been conducting almost annual initiatives focusing on food safety,” says Richard at IDDBA. “We created our first initiative about five years ago—Safe Food Matters, which addressed Listeria and food allergens, among other topics. Our online library includes food safety training videos.”

IDDBA also provides job guides—one- page pdfs with food safety information for retail associates at the store level.

“We’ve tried to build awareness around the importance of food safety at the store and company levels, because this subject is universal,” says Richard. “Even though IDDBA doesn’t have a program, we’ve come up with other ways to educate mem- bers and build awareness. This includes campaigns with documents and videos on our website.”

The association also has worked with the FDA in conducting webinars for its members on legislation and regulations.

“We have a great relationship with the FDA and have worked to educate members primarily through webinars about FSMA,” Richard says. “We also have members who offer guidance and services in helping com- panies become compliant and have worked with them on webinars that are offered to everyone, not just IDDBA members.”

IDDBA has received positive feedback on its food safety initiatives and constantly emphasizes the importance of this issue.

“The more awareness we build around food safety, the stronger our industry will be,” says Richard. DB

1 of 8 article in DeliBusiness Apr/May 2020